Polypropylene, Polyethylene and PVC tank manufacturing.

Fully automated 15 ton cranes for Electro winning and recovery of tin from tin plated product. The pressed bales are sent for re smelting after tin recovery.

Chromic Acid, Sulphuric Acid and Tartaric Sulphuric Acid Anodising plant manufacturing Structural components for Boeing and Airbus.

PVC Horizontal scrubber with RO water storage

Effluent water reclaim plant skid mounted with control system. Plant uses Microfiltration to remove all solids before recycling 70% of effluent water with RO membranes at 7000 l/h.

Metal Pre Treatment plant for pressed steel and mild steel filter components for Powder Coating plant.

Plant installation at various sites with Structural, Mechanical, Electrical and Software work being done in-house.

164 Chemical tanks installed for Aviation industry with 7 automated carriers for NADCAP specification in Copper, Nickel, Silver, Cadmium, Chrome, Hard Chrome, Tartaric Sulphuric Acid Anodising and Chromic Acid Anodising.

Siemens PLC and HMI control panels for NADCAP. Nadcap accreditation is an industry driven program where highly qualified individuals, having experience in the aerospace industry conduct the actual process audits, using criteria specific to an actual process. This accreditation is intended for organizations doing business in the aerospace industry.

Turnkey Water treatment plant. 5000 l/h RO Plant skid mounted being delivered. Effluent water recycling skid mount plant 7000 l/h with Microfiltration and 70% effluent water recovery through RO.

Motor Industry Metal Pre Treatment and Zinc Phosphate plant treating Mild Steel, Cast Steel and Galvanised Steel product.

ANODISING plant for various aviation structural components with advanced extraction and scrubbers.

Automated position control 10 ton crane system for gravity feed wine cellar.

Electrical and process control cabinet for NADCAP plant showing PLC, Drives, Motor Starters, cable racks and distribution panels.

Various control cabinets with PLC and multiple VFD controlled via Totally Integrated Automation on Profibus Communication system

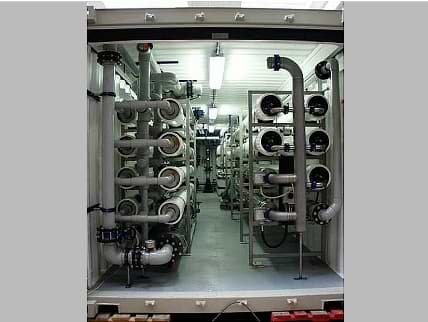

Containerised RO Plant 15000 l/h capacity.

5000 l/h RO water plant producing <10 microsiemen water loaded for delivery.

Fully Automated 600Kg carrier used on an Anodising plant showing Polypropylene tanks with lip extraction plenums and extraction ducts.